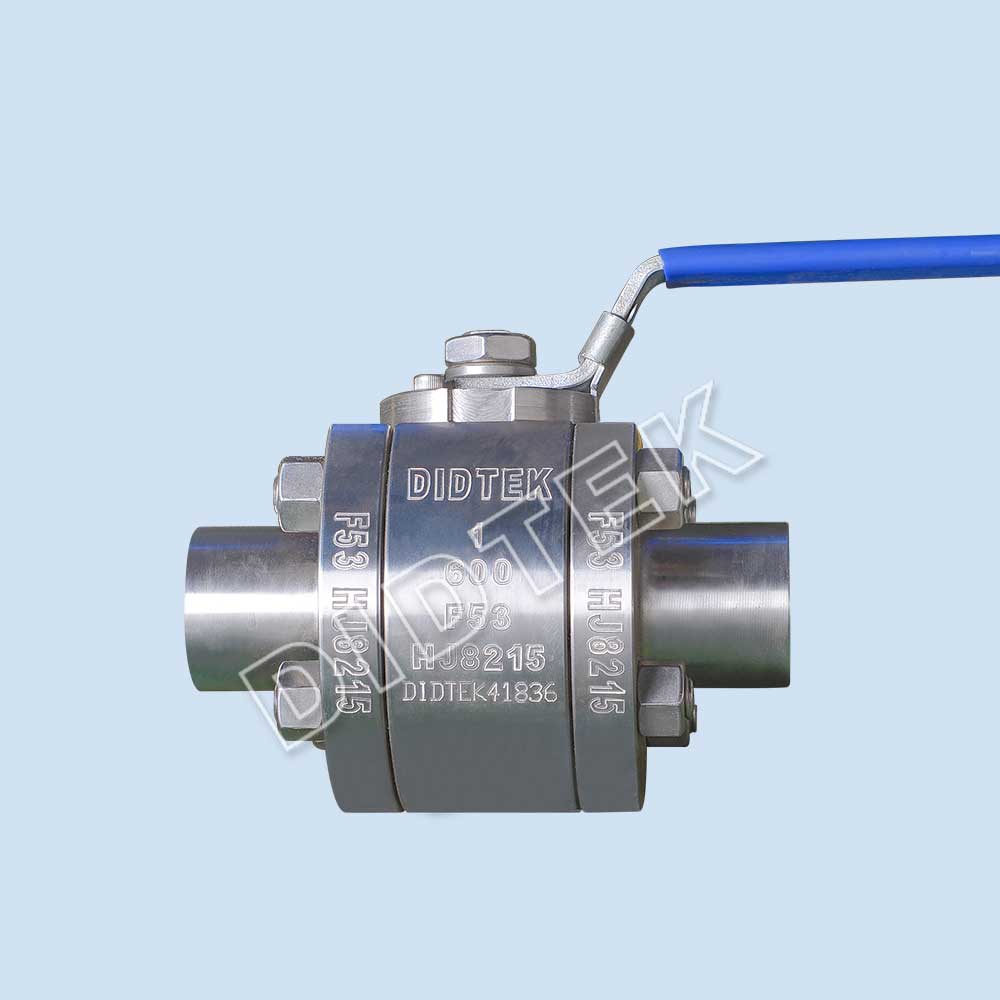

Size Range

1/2"~8"

Temperature Range

-196℃~650℃

Pressure Rating

ASME CL, 150, 300, 600

1. A patent-pending seat design provides automatic cavity relief without requiring a vented ball or external relief valve. API Spec 6D monogram is available upon request.

2. A variety of actuator types, including pneumatic, hydraulic, diaphragm, vane, electromechanical, and electrohydraulic, can be easily installed.

3. The inline valve stem packing options consist of PTFE or graphite. The packing is field adjustable and virtually never requires lubrication.

4. Didtek Ball Valves cana be supplied and certified to meet the requirements of fugitive emissions (FE) as regulated by ISO and API.

5. The stem is positively retained and cannot be removed with the valve in service.

Didtek Forged Floating Ball Valve can be used to handle a variety of liquids, suspended solids and gases in many type of industry. Ball valves are suited for fluid flow requiring assured performance, tight shutoff, constant torque and no maintenance.

1/2'' to 8''

F53

-196 to 650°C

Monel

ASME CL150, 300, 600

PTFE

Zero Leakage

ASTM B148 C63200

Two Piece

API 6D

Flanged

API 598

Lioyd's CE, Lioyd's UKCA, EAC, ISO 9001, API 6D, API 6FA

Full

ASME B16.10

Oil and Gas Pipeline, Offshore Platforms, Onshore Terminals, Emergency Shutdown, Suction and Discharge Isolation, Block and Bypass, Pumping, Compression and Reinjection Units, Metering Stations, Pig Traps, Surge-Relief Skids, Decoking Isolation, Buried Services, Produced Water (Brine) Services