Size Range

1/2"~8"

Temperature Range

-196℃~650℃

Pressure Rating

ASME CL, 150, 300, 600

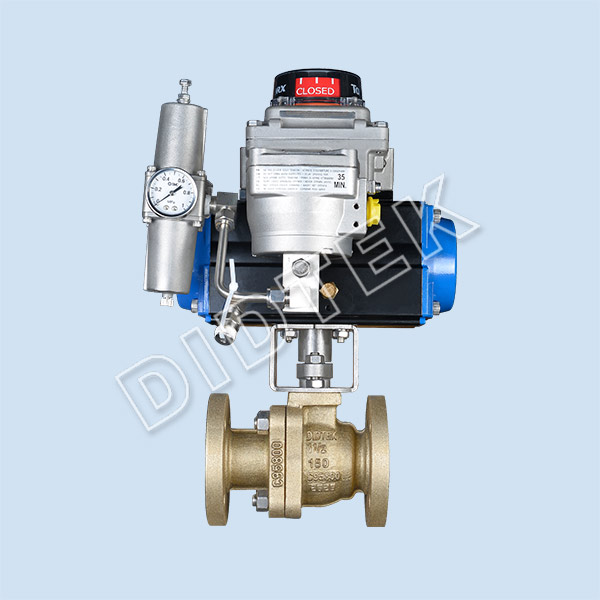

1. This safe and efficient operation single piece floating ball valve is non-directional and can be installed in either end of the pipeline.

2. This floating ball valve is designed and manufactured with ASME/API, ISO and JIS standards and can be made of stainless steel and carbon steel materials.

3. The 2-piece flanged end floating ball valve from Kinvalve is available in stainless steel and carbon steel bodies.

4. Available in sizes form 1/2″ – 12″, they come with an ISO 5211 mounting pad for automatic actuation.

5. Meeting all Class requirements, this ball valve is relatively affordable and offers excellent versatility in application.

6. Didtek’s full-port design, flanged end 3-piece floating ball valves are ideal for the safest inline maintenance.

7. The valves come with a blowout-proof stem design.

Didtek High Quality Floating Ball Valve with all of the technical features needed for the most demanding Industrial Applications. Designed for Safety, Low Emissions, Long Service Life, and ease of Maintenance, this series is available in Split-Body Full and Reduced Port styles as well as One-Piece (Unibody) reduced port construction. Available in Exotic Alloys as well as more common materials, the PF Series should be your go-to choice for Critical and Toxic Services in applications for the Chemical, Petrochemical, Refining, Upstream and Midstream Oil and Gas Industries and more.

1/2'' to 8''

C95800

-196 to 650°C

Monel

ASME CL150, 300, 600

PTFE

Zero Leakage

ASTM B148 C63200

Two Piece

API 6D

Flanged

API 598

Lioyd's CE, Lioyd's UKCA, EAC, ISO 9001, API 6D, API 6FA

Full

ASME B16.10

Oil and Gas Pipeline, Offshore Platforms, Onshore Terminals, Emergency Shutdown, Suction and Discharge Isolation, Block and Bypass, Pumping, Compression and Reinjection Units, Metering Stations, Pig Traps, Surge-Relief Skids, Decoking Isolation, Buried Services, Produced Water (Brine) Services