Cast Floating Ball Valve

Didtek Cast Floating Soft Seat Ball Valve are ideal where chemical compliance is required. They are made of thermoplastic material and not recommended for abrasive, dirty liquids as they can break down easily. They work best in medium pressures and temperatures below 260°C.

Corrosion Resistant PEEK 317 Ball Valve

Features & Benefits

1. Didtek Ball Valve Stem head design provides mounting of the lever handle always in parallel to the flow passage. Misalignment of the handle is thus prevented.

2. The lower end of the stem is designed with an integral collar to be blowout-proof. It also functions as the backseat for assured stem sealing.

3. An antistatic feature is provided to ensure electrical continuity between ball, stem, and body.

4. Facility for mounting a locking device for prevention of accidental valve operation is provided.

5. Plant fires are a serious concern for soft-seated ball valves because of possible fluid leakage and consequent increase of the fire magnitude caused by deterioration of resilient sealing materials.

6. Didtek ball valves are engineered for fires safety and successfully fire tested to minimize both external and internal fluid leakage after plant fires.

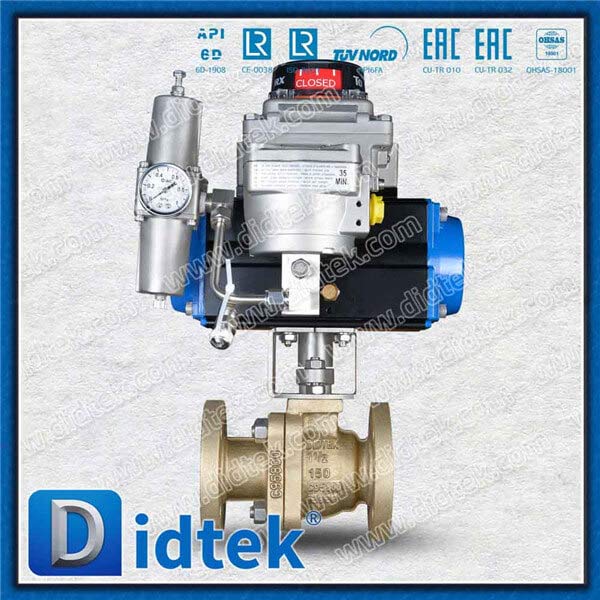

ATEX Electric Actuated Motor Ball Valve

Features & Benefits

1. Didtek Ball Valve can be quickly opened and closed with a quarter turn movement

2. Ensure a very tight seal without the need for high torque forces

3. have a compact design (this is the main difference between a ball valve and a gate valve – which are both on/off devices).

4. In a floating valve, the ball is suspended in the flowing fluid and is kept in position by the compression of two elastomeric seats against it.

5. Plant fires are a serious concern for soft-seated ball valves because of possible fluid leakage and consequent increase of the fire magnitude caused by deterioration of resilient sealing materials.

6. The “Full port” (FB) type features a bore size (the hole of the ball) matching the bore size of the connected piping. Full port ball valves minimize the pressure drop that is generated by reduced port valves but they are of course more bulky, heavy and expensive. FB ball valves are better suited, than RB ball valves, for throttling applications.

Automation Electric Motor Operator DBB Ball Valve

Features & Benefits

1. This safe and efficient operation single piece floating ball valve is non-directional and can be installed in either end of the pipeline.

2. This floating ball valve is designed and manufactured with ASME/API, ISO and JIS standards and can be made of stainless steel and carbon steel materials.

3. The 2-piece flanged end floating ball valve from Kinvalve is available in stainless steel and carbon steel bodies.

4. Available in sizes form 1/2″ – 12″, they come with an ISO 5211 mounting pad for automatic actuation.

5. Meeting all Class requirements, this ball valve is relatively affordable and offers excellent versatility in application.

6. Didtek’s full-port design, flanged end 3-piece floating ball valves are ideal for the safest inline maintenance.

7. The valves come with a blowout-proof stem design.